Below the line is an experimental conversion of PDF to MediaWiki, via Word, using Zamzar.com and wikEd. The wikEd step (which is usually good) has trouble and gives lots of broken table formatting.

| File:.jpg HUMAN-POWERED

WATER-LIFTERS

|}| The choice of water lifters available is large and varied, making the selection of an

appropriate device difficult. In America and Europe during the 19th century the design of

mass-produced hand pumps evolved by trial and error rather than through scientific

research and development. There is now a large number of adequate, rather than

optimum, designs conceived by local manufacturers, and it is hard to know which pump is

the best for each application. This brief presents an overview of the types of human-

powered water-lifters available, the applications appropriate to them and their comparative

advantages.

Water-lifters can be broken down into the following categories:

|}| •

•

|}| Groundwater (open-well, shallow-well and deep-well pumps)

Surface Water (shadouf, dhone, chain and washer and archimedean screw)

|}| Groundwater

When rain falls, it seeps into the ground and collects in an underground reservoir known

as groundwater. The upper limit of this reservoir, the "water-table", may vary in depth, from

just below the surface (like in a spring or oasis) to well over 100 metres. The only way to

get at this water is to dig down.

Open-well

The simplest and cheapest method of lifting groundwater remains the rope and bucket in a

wide, shallow well. These can operate to a depth of 100 metres, although they rarely

exceed 45 metres, and can last for a very long time without maintenance. It is worth

considering this design before proceeding with more complicated methods.

It may not be possible to construct an open-well if the water table is too deep or if the

foundations are very hard (such as rock) or very soft (such as fine running sands). These

restrictions also depend on the method of construction.

If the groundwater can only be accessed through a bore, then a groundwater pump must

be used. Groundwater pumps can be split into two categories, shallow-well and deep-well.

Shallow-well pumps

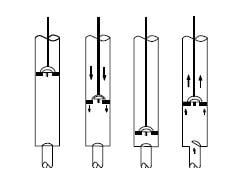

Most types of groundwater pump have

a piston that moves back and forth

inside a two-valve cylinder (a valve

allows water to pass in only one

direction - in this case, upwards):

Suction pumps have the cylinder

situated above ground or near the

surface. This means that they can

only be used for shallow wells. It is

called a suction pump because pulling

up on the piston creates a low

pressure ("suction") in the cylinder,

|}| causing the atmospheric pressure

outside to push the water up to the

surface. Because atmospheric

|}| Figure 1: How most types of pump cylinders work

|}| pressure is fairly low, the pressure difference between inside and outside the cylinder is only large

|}| Intermediate Technology Development Group

|}| enough to raise water from a maximum depth of about 7 metres.

|}| It should also be noted that if a shallow-well is used too much, the water-table may fall as the

underground reservoir of water is reduced. If this level falls below 7 metres, the pump will not

work.

Four types of shallow-well pumps are shown below: rower, piston, diaphragm and semi-rotary.

Rower

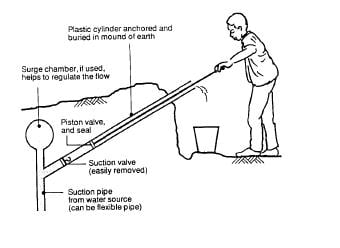

The rower pump is a simpler and

cheaper version of the traditional

piston pump (see below). Its

simple design means it can be

easily manufactured and

maintained using locally available

skills and materials. This type of

pump may require "priming",

which means pouring water into

the cylinder so that the seal

around the piston is airtight. It is

very important that clean water is

used, to avoid contamination of

the pump and the spread of

water-borne diseases.

Figure 2: Rower pump

Piston

Piston pumps, based on the same design as

shown in Figure 1, are more widely used. There

is a similar risk of contamination from dirty

priming water. In cases where the water is to be

delivered under pressure (such as to a village

water mains) or to a point higher than the

cylinder (such as a water storage tank), a "force"

pump is required. The operation is the same, but

the design is slightly altered so that the top is

airtight. This is done by putting a valve on the

spout and adding a "trap tube" and air chamber

which maintains the pressure (and therefore the

flow) during the up-stroke.

|}| Figure 3: Shallow-well piston pump

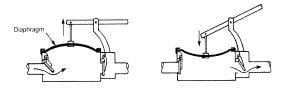

Diaphragm

This design is often used for fuel pumps in

cars. The Vergnet pump is an adaptation

of this principle for deep-well use, which

can be used in crooked wells, where a rod-

operated pump would have problems, and

which is fairly easy to maintain.

|}| Figure 4:

|}| Diaphragm pump

|}| 2

|}| Intermediate Technology Development Group

|}| Because leg muscles are stronger than arm muscles, this design is less tiring to use.

Most of the parts can be manufactured locally, the exceptions being the cylinders and

pulley.

|}| Figure 5: Treadle pump

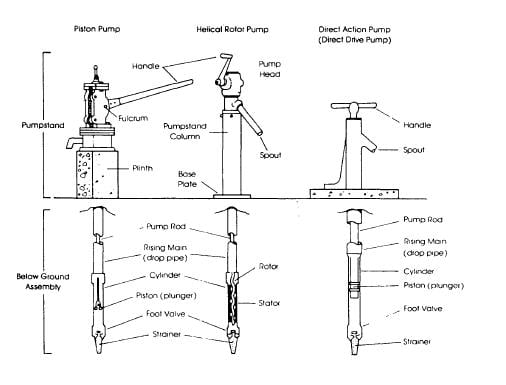

Deep-well pumps

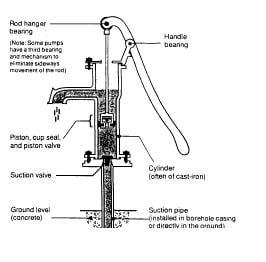

Deep-well pumps can be used for depths over 7 metres because the cylinder or lifting device is

below ground, as shown in Figure 6, often below the groundwater line. They are often known as

"lift" pumps because they do not rely on suction to raise the water. As a result of their depth, they

are harder to maintain than surface pumps, since the pump-rod must be removed to get at the

cylinder. Like suction pumps, lift pumps can be made into force pumps by the addition of a spout

valve, air chamber and trap tube. Three types of deep-well pump are described below: piston,

helical rotor and direct action.

Piston

The design is very similar to the shallow-well pump and is capable of lifting water from depths of up

to 50 metres. However, the cylinder is situated deep underground, below the groundwater-line,

connected to the pump handle via a long rod called a "pump rod" (see Figure 6). Sometimes the

outside pipe, called the "rising main", is of a larger diameter so that it is possible to pull the whole

cylinder up to the surface for repair without taking the pump apart. However, this is more

expensive.

'Helical rotor (or "progressive cavity") '

Helical rotors are capable of lifting water from depths of up to 100 metres. Instead of a piston,

there is a metal "rotor" which has a corkscrew shape and which turns inside a rubber "stator" or

sleeve (see Figure 6). The lever is replaced with one or two turning handles.

'Direct action ( or "direct drive") '

This design is capable of lifting from a depth of 12 metres. The narrow pump rod is replaced by a

hollow plastic pipe which displaces water as the pump handle is pushed down. During the up-

stroke, the pipe acts as a pump rod, the valve on the piston

closes and water is lifted up. The pump is therefore capable of pushing water up the rising main

during both strokes. Because the pipe is hollow, it floats, so the handle does not have to be pulled

up so hard.

|}| 3

|}| Intermediate Technology Development Group

|}| Figure 6:

|}| Types of deep-well lift pumps - piston, helical rotor and direct action

|}| Surface Water

Surface water lifters are generally less complicated than groundwater lifters, because the water is

so much more accessible. Four types are described below: shadouf, dhone, chain and washer

and archimedean screw.

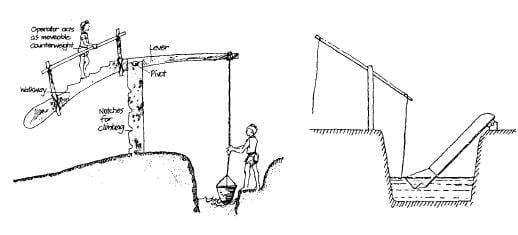

Shadouf (picottah)

The basic shadouf consists of a rope, pole, bucket and counterweight and is capable of lifting

water up to 4 metres. The counterweight can be just a heavy rock, but in the more advanced

"picottah" design, one person guides the bucket while the other acts as a moving counterweight.

|}| 4

|}| Intermediate Technology Development Group

|}| Dhone

This design replaces the bucket with a channel. It can also be adapted for picottah-style

operation.

|}| Figure 7:

|}| Picottah-style shadouf and dhone

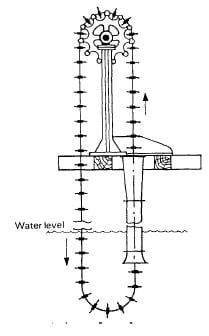

|}| Chain/rope and washer (or "paternoster")

These pumps have been used in China and Europe

for many centuries. Water is lifted by close-fitting

washers in a pipe. Although in theory it is possible

to construct a vertical chain and washer pump to

raise water to any height, most do not exceed 20

metres. A variation of this design is called the

"dragon-spine" pump, which lies at a shallow angle

to the horizontal. In this case, lifting height is

rarely more than 6 metres. However, the design is

very flexible and can easily be adapted to

circumstances.

|}| Figure 8:

|}| Chain and washer pump

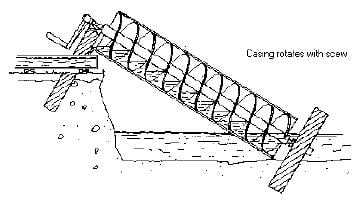

|}| Archimedean screw

Although this design looks quite complicated, it is fairly easy to build using local materials and is

readily transportable. The inside, which is shaped like a corkscrew, is turned by a handle, trapping

water in the cavities as shown in Figure 9. Although on a much larger scale, this is very similar to

the operation of the helical rotor. However, the lifting range is much smaller.

|}| 5

|}| Intermediate Technology Development Group

|}| Figure 9:

|}| Archimedean screw

|}| Selecting a water-lifter

The choice of water-lifter is determined by the application and the resources available to the

users. Demand for water may come from domestic, community, industrial and agricultural

needs. It is first necessary to determine:

|}| •

•

|}| where the water will come from (the source)

where it will go to (the destination)

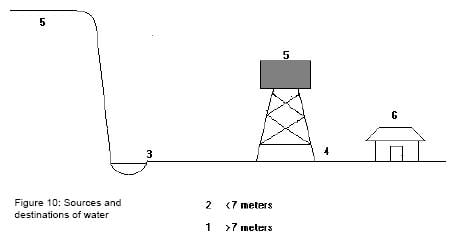

|}| Figure 10 shows the types of source and destination to be considered.

|}| Figure 10: Sources and

destinations of water

Once the source and destination has been determined, it is possible to narrow down the choice

of water-lifter. The table below summarises the options available for different combinations of source

and destination.

Source

|}| Destination

4 (Surface)

5 (hill/tank)

6 (village)

|}| 1. (> 7m)

Deep-well Lift Pump

Deep-well lift & Force

Pump

Dee-well lift & Force

Pump

|}| 2. (<7m)

Shallow well suction

pump or open-well

Shallow-well force

pump

Shallow-well force

pump

|}| 3. (river/pool)

Shallow-well suction

pump

Surface water system

or suction & force

Shallow well force

pump

|}| 6

|}|  Human Powered Water Lifting Devices

Human Powered Water Lifting Devices

Table 1: Water-lifter options

|}| Intermediate Technology Development Group

|}| Apart from the source and destination of the water, there are many other criteria which should be

considered before making a selection. Where possible, the lifter should be suitable for Village

Level Operation and Maintenance (VLOM) or Management of Maintenance (VLOMM). This

reduces the reliance of the villagers upon large institutions to sustain the development of the water

supply. A check-list of things to consider when choosing a pump is shown below.

Capital cost

How much does the lifter cost initially?

Will a loan be needed, or does the village have sufficient funds?

Running cost

What is the on-going cost of operating the lifter?

Does the village have sufficient manpower available to operate the lifter for all the time it is

needed?

Maintenance cost

What is the cost of and skill required for the maintenance of the lifter?

Can the pump be repaired in the village or somewhere nearby?

Are spare parts available?

Can the villagers afford them? How often is it likely to need repair?

How long would it take to repair the lifter and what will the villagers do in the meantime?

'NB Maintenance is an integral part of lifter management. For more complicated designs, such as '

the deep-well pumps, it is important that this maintenance is preventative. Problems should be

avoided by regular inspection and servicing of the mechanical parts. Wear and tear will be less

severe this way, and any problems will be solved before they cause more damage.

Manufacture and materials

Can the lifter be manufactured locally using local skills and materials?

Life expectancy

How long is the lifter expected to last before it has to be replaced?

How resistant is the lifter to abuse?

Lift height and flow rate

How much water does the community need? The maximum flow capacity of the lifter should be

matched to the demand from the community, including home, industrial and irrigation needs. (In

the case of pumps, this flow rate given by the flow-rate/lift-height, or "Q/h", curve, which should

be supplied by the manufacturer)

How high does the lifter have to raise the water?

How deep is the groundwater and is it likely to fall in future (such as from over-use)?

Operators

Is the lifter suitable and acceptable to the people who will actually operate it?

Are there health and safety considerations, such as dangerous machinery or risk of

contamination?

Is the operation ergonomic (comfortable to use)? For instance, are the average and maximum

handle forces required realistic for women and children?

Community

Is there a capable community organisation which can oversee maintenance and management of

the device and the water?

Will the users be instructed how to use and look after the device?

|}| Table 2 below gives a summary of some of these criteria for each of the designs. The values given

are very approximate, and should be taken only as a rough guide. As lift height increases, flow

7

|}| Intermediate Technology Development Group

|}| rate falls, so at maximum lift, the actual flow rate will be much less than the maximum flow rate.

Also, the flow rates are given for one person operating the pumps, except in the case of the

picottah, which requires a minimum of two.

Table 2: Assessment criteria

|}| Type

|}| SUCTION

Rower

Suction piston

Diaphragm

Treadle

LIFT

Rope and bucket

Lift piston

Helical rotor

Direct action

SURFACE WATER

Shadouf

Picottah

Dhone

Chain and washer

Archimedean screw

|}| Construction

(Traditional/

Industrial)

Traditional

Industrial

Industrial

Traditional

|}| Maximum

lift height

(metres)

7

7

7

7

|}| Maximum

flow rate

(m' 3'/hour)

3

8

10

18

|}| Traditional

Industrial

Industrial

Industrial

|}| 100

50

100

15

|}| 15

1.5

1.5

1

|}| Traditional

Traditional

Traditional

Trad / Industrial

Traditional

|}| 4

8

1.5

15

1.5

|}| 6

6

6

25

25

|}| References and resources

Resources

|}| •

•

•

•

•

|}| Human and Animal-powered Water-lifting Devices: A state-of-the-art survey

by W. K. Kennedy & T. A. Rolgers. ITDG Publishing, 1985.

Water pumping devices - A handbook for users and choosers

by Peter Fraenkel, ITDG Publishing, 1986.

Tools for Agriculture - a buyer's guide to appropriate equipment

Introduction by Iab Carruthers & Marc Rodriguez, ITDG Publishing, 1992.

How To Make and Use The Treadle Irrigation Pump

by Carl Bielenberg and Hugh Allen, ITDG Publishing, 1995.

How to Make a Rope-and-Washer Pump by Robert Lambert, ITDG Publishing, 1990. '

|}| ITDG Publishing

103-105 Southampton Row

London, WC1B 4HH, UK

Tel: +44 (0)20 7436 9761

Fax: +44 (0)20 7436 2013

E-mail: orders@itpubs.org.uk

Website: http://www.developmentbkookshop.com

|}| 8

|}| Intermediate Technology Development Group

|}| Organizations

Sue Sherry

WELL

London School of Hygiene & Tropical Medicine

Keppel Street, London, WC1E 7HT, United Kingdom

Tel: +44(0)20 7927 2214

Fax: +44(0)20 7636 7843

E-mail: well@lshtm.ac.uk

Web page: http://web.archive.org/web/20170717112937/http://www.lboro.ac.uk:80/well/

WELL is a resource centre funded by the DfID to promote environmental health and well being in

developing and transitional countries. It is managed by the London School of Hygiene and

Tropical Medicine (LSHTM) and the Water, Engineering and Development Centre (WEDC),

Loughborough University for British & Southern NGOs working in water & sanitation.

WaterAid

Prince Consort House, 27-29 Albert Embankment, London, SE1 7UB, UK

Tel: +44 (0)20 7793 4500

Fax: +44 (0)20 7793 4545

E-mail: technicalenquiryservice@wateraid.org.uk

Web Page: http://www.wateraid.org.uk

VITA

Volunteers in Technical Assistance

1600 Wilson Boulevard - Suite 710

Arlington, Virginia 22209, USA

Tel: +1 703 276 1800

Fax: +1 703 243 1865

E-mail: vita@vita.org

Web Page: http://www.vita.org

The World Health Organization

Headquarters Office in Geneva (HQ)

Avenue Appia 20

1211 Geneva 27

Switzerland

Tel: +41 22 791 21 11

Fax: +41 22 791 3111

Website: http://www.who.int

Manufacturers

This is a selective list of suppliers and does not imply ITDG endorsement. There is a very large

number of manufacturers in India; more can be found in "Tools for Agriculture" (see below).

Steelman Indisutries

Shanti Dham, Kankarbagh Main Road, Patna (Bihar) - 800 020, India

Tel: +91-612-352530

Fax: +91-612-352872

E-mail: manraw@hotmail.com

Web page: http://www.geocities.com/Eureka/park/4967/

Produce the following handpumps: India Mark II, India Mark III, India Mark IV, Rawman shallow &

force handpump, Rawman special Lift & force VLOM handpump

Ajay Industrial Corporation

4561 Deputy Ganj, Sadar Bazar, Delhi-110006, India

Tel: +91 11 3545291/ 3611140/ 3612204/ 3612206/ 3616816

9

|}|  Human Powered Water Lifting Devices

Human Powered Water Lifting Devices

Fax: +91 11 3536205

E-mail: ppp@del3.vsnl.net.in

Web page: http://web.archive.org/web/20180329051419/http://ajayindcorp.com//

|}| Intermediate Technology Development Group

|}| Manufacture a wide variety of handpumps including: India Mark II, India Mark III, Afridev, Treadle pump.

|}| Manufacturers

Van Reekum Materials bv

P. O. Box 98, 7300 AB Apeldoorn, Netherlands

Tel: +31 55 533 54 66

Fax: +31 55 533 54 88

E-mail: info@reekum.nl

Web page: www.reekum.nl

Producers of a range of pumping equipment

Mono Pumps Limited

Martin Street, Audenshaw, Manchester M34 5DQ, England, United Kingdom

Tel: +44 (0)161 339 9000

Fax :+44 (0)161 344 0727

Email:info@mono-pumps.com

Web site: http://www,mono.pumps.com

Producers of helical rotor and piston lift device

Monoflo Incorporated

16503 Park Row, Houston, Texas 77084, U.S.A.

Tel: +1 281 599 4700

Fax: +1 281 599 4733

Email: inquire@monoflo.com

SWS Filtration Ltd.

The Bakers Chest, Hartburn, Morpeth, Northumberland NE61 4JB, United Kingdom

Tel +44 (0)1670 772214

Fax +44 (0)1670 772363

E-mail: swsfilt@dial.pipex.com

Manufactures of Rower and other low-technology pumps

H.J.Godwin Ltd.

Quenington, Cirencester, Glos, GL7 5BX, United Kingdom

Tel +44 (0)1285 750271

Fax +44 (0)1285 750352

Deep-well and shallow-well pumps

Prodorite (Pvt) Ltd

21 Leyland Road, Arbennie Industrial Sites, PO Box 2887, Harare, Zimbabwe

Tel: +263 4 663691/4

Fax: +263 4 663696

Products include hand pumps for wells, water storage tanks, Blair vent pipes and sanitary pans

Consallen Group of Companies, P.O. Box 2993, Sundury, Suffolk, CO10 0TY, United Kingdom

Tel/Fax: +44 (0)1787 881115

E-mail: dvallen@compuserve.com

Website: http://web.archive.org/web/20050320053306/http://ourworld.compuserve.com:80/homepages/dvallen/

Specialists in Rural Water Supply & VLOM Handpumps

|}| 10

|}