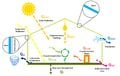

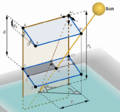

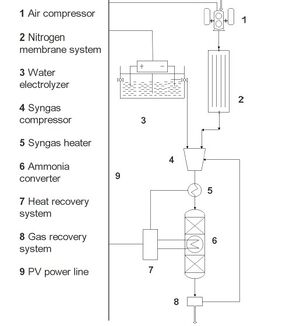

Ammonia synthesis is the most important step for nitrogen-fertilizer production and consumes approximately 1% of the world’s energy production and energy-related greenhouse gas emissions. In addition to the concomitant emissions caused by ammonia and nitrogen fertilizer synthesis, centrally produced fertilizer that must be distributed to farms also harms the environment because of the embodied energy of transportation. An environmentally-optimal nitrogen fertilizer system would be distributed on farms themselves using only renewable inputs. Recent developments in solar photovoltaic technology and subsystems for ammonia production have made non-organic on-site ammonia production physically possible. This study provides a technical evaluation of the process for on-site nitrogen-fertilization of corn using solar photovoltaic electricity as the energy input. The system consists of a water electrolysis system to generate hydrogen and a membrane system to generate nitrogen needed as material inputs. Total power consumption for syngas preparation to generate a unit of ammonia is calculated. System total energy consumption is calculated while compensating syngas preparation with heat recovery. Five case-study locations are evaluated to determine their suggested nitrogen fertilizer addition (N-rate) for corn growth and the energy consumption for suggested N-rate is calculated. The System Advisor Model (SAM) is then used to simulate the PV system output for those five locations. Finally, the PV land use required as a fraction of the corn field area is determined. The results indicate that because PV is so much more efficient at solar energy conversion than organic methods, even the worst case evaluated in Indiana requires less than 1% of the corn field converted to a PV system to provide enough energy to generate sufficient amounts of ammonia for fertilizer for the remaining corn. The system was modeled to provide ammonia to fertilize for corn fields larger than 1079 acres with the worst soil conditions, the area of which applies to more than half of cropland in the U.S. in 2011. As the finiteness and emissions of fossil fuel production of nitrogen become more important, this renewable system should become economical and future investigations into its overall viability are warranted.

Highlights[edit | edit source]

- Environmental nitrogen fertilizer system is distributed using renewable energy.

- Energy consumption to generate N using water electrolyzer has been calculated.

- Energy consumption to provide N fertilizer for unit corn field has been calculated.

- Land required for photovoltaic fertilizer production for corn has been simulated.

- Results show <1% of the corn field converted to a PV system for N-fertilizer energy.

See also[edit | edit source]

- Coal with Carbon Capture and Sequestration is not as Land Use Efficient as Solar Photovoltaic Technology for Climate Neutral Electricity Production

- Dual use of land for PV farms and agriculture literature review

- sheep

- Israeli white plastic reflectors

- A Farmer's Guide to Going Solar (NREL)

- German guidelines: https://www.ise.fraunhofer.de/content/dam/ise/en/documents/publications/studies/APV-Guideline.pdf

- 2021 review

- Miskin, C.K., Li, Y., Perna, A., Ellis, R.G., Grubbs, E.K., Bermel, P. and Agrawal, R., 2019. Sustainable co-production of food and solar power to relax land-use constraints. Nature Sustainability, 2(10), pp.972-980.

- Retrofitting solar parks for agrivoltaics

- Shading PV

- Alexis' talk at American Solar Grazing Association2021

In the News[edit source]

- Agrivoltaics: solar energy + better crops Climate and Nature

- Why solar power and farmers’ fields could be the perfect combination TVO

- Solar farms and sheep show the makings of a clean energy classic duo Business Renewables

- Agrivoltaics charge up St. Albert-area farms St Albert Gazette

- Sheep, solar and crops. How some Alberta farms are creating ideal growing conditions Western Wheel

- Sheep, solar and crops. How some Alberta farms create ideal growing conditions Voxpopuli

- Protein bars from recycled plastic bottles? An indoor farm on wheels? Western prof gets innovative with green tech Toronto Star

- 加拿大环保狂人回收塑料瓶制成蛋白棒 还有可移动室内农场!? Lahoo