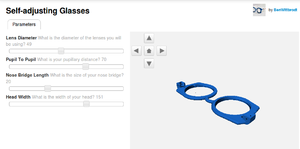

Although the trend in manufacturing has been towards centralization to leverage economies of scale, the recent rapid technical development of open-source 3-D printers enables low-cost distributed bespoke production. This paper explores the potential advantages of a distributed manufacturing model of high-value products by investigating the application of 3-D printing to self-refraction eyeglasses. A series of parametric 3-D printable designs is developed, fabricated and tested to overcome limitations identified with mass-manufactured self-correcting eyeglasses designed for the developing world's poor. By utilizing 3-D printable self-adjustable glasses, communities not only gain access to far more diversity in product design, as the glasses can be customized for the individual, but 3-D printing also offers the potential for significant cost reductions. The results show that distributed manufacturing with open-source 3-D printing can empower developing world communities through the ability to print less expensive and customized self-adjusting eyeglasses. This offers the potential to displace both centrally manufactured conventional and self-adjusting glasses while completely eliminating the costs of the conventional optics correction experience, including those of highly-trained optometrists and ophthalmologists and their associated equipment. Although, this study only analyzed a single product, it is clear that other products would benefit from the same approach in isolated regions of the developing world.

Additional Information[edit | edit source]

- Self-adjustable glasses literature review

- Collection of 3D printed glasses designs - some may be useful ideas

- Customizable glasses design for this paper

- OpenSCAD files:

See also[edit | edit source]

- Open-source, self-replicating 3-D printer factory for small-business manufacturing

- Open-source Lab

- Open source optics

- Open source 3-D printing of OSAT

- Open-source hardware

- OphthalmicDocs Fundus - a 3D printed universal smartphone retinal imaging adapter.

- Distributed manufacturing with 3-D printing: a case study of recreational vehicle solar photovoltaic mounting systems

- Global value chains from a 3D printing perspective

- Development of a Resilient 3-D Printer for Humanitarian Crisis Response

- Open-source 3-D Printing in Managing Humanitarian Innovation