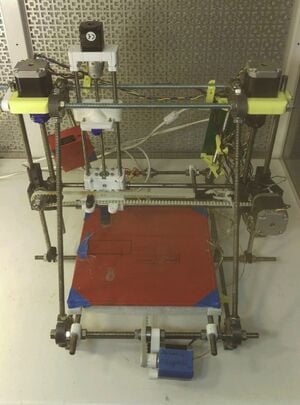

Slot die coating is growing in popularity because it is a low operational cost and easily scaled processing technique for depositing thin and uniform films rapidly, while minimizing material waste. The complex inner geometry of conventional slot dies require expensive machining that limits accessibility and experimentation. In order to overcome these issues this study follows an open hardware approach, which uses an open source 3-D printer to both fabricate the slot die and then to functionalize a 3-D slot die printing system. Polymer materials are tested and selected for compatibility with common solvents and used to fabricate a custom slot die head. This slot die is then integrated into a 3-D printer augmented with a syringe pump to form an additive manufacturing platform for thin film semiconductor devices. The full design of the slot die system is disclosed here using an open source license including software and operational protocols. This study demonstrates that functional lab-grade slot dies may be 3-D printed using low-cost open source hardware methods A case study using NiO2 found an RMS value 0.486 nm, thickness of 17–49 nm, and a maximum optical transmission of 99.1%, which shows this additive manufacturing approach to slot die depositions as well of fabrication is capable of producing viable layers of advanced electronic materials. Using this method, a cost savings of over 17,000% was obtained when compared to commercial slot die systems for laboratories.

- open hardware source code - Open Source 3-D Printable Slot Die.<ref>https://osf.io/m2zqk/<ref>* Franklin firmware

- OpenSCAD:<ref>http://www.openscad.org/<ref>* Open-source syringe pump

- Prusa conversion - follow same procedure as Open-source Wax RepRap 3-D Printer for Rapid Prototyping Paper-Based Microfluidics with the new x carriage provided in this paper.<ref>https://osf.io/m2zqk/<ref>

Highlights[edit | edit source]

- Open source 3-D printer to both fabricate slot die and functionalize.

- Created a 3-D slot die printing system.

- Functional lab-grade slot dies may be 3-D printed.

- Semiconductor films deposited with polymer slot die down to 17 nm.

See also[edit | edit source]

- RepRap

- Free and Open-source Control Software for 3-D Motion and Processing

- Ystruder: open source multifunction extruder with sensing and monitoring capabilities

In the News[edit | edit source]

- Michigan Tech's open-source parametric 3D printed slot die system is 17,000% cheaper than commercial ones 3Ders

- Michigan Tech的开源参数3D打印槽模具系统比商业产品便宜17,000% 3D Wang

- 17,000% Cost Reduction with Open Source 3D Printing: Michigan Tech Study Showcases Parametric 3D Printed Slot Die System - 3D Print

- 研究员开发出比商业产品便宜17,000%的开源参数化3D打印槽模系统 - 3D Hoo

- 研究員開發出比商業產品便宜17,000%的開源參數化3D列印槽模系統 -KK News

- Michigan Technological University per il sistema di fustellatura a fessura con stampa 3D parametrica open source per l'elaborazione di semiconduttori a film sottile - Stampare in 3D

- Open Source 3D printing cuts cost from $4,000 to only $0.25 says new study - 3D Printing Industry