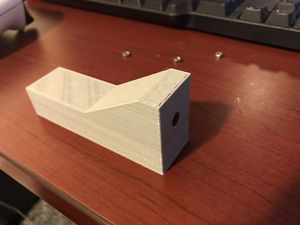

High school shop teachers are on a tighter budget now than ever, and the trades are in higher demand today in local high schools. In wood shop, a lot of tools can cost a lot of money, even the smaller tools. One of these small tools that costs over 20 dollars is a Kreg Pocket Hole Jig. These jigs are used to make holes to join together pieces of wood in products such as tables, clocks, nightstands, or any fine finished wood product. With different sizes of wood and different hardware needed, these jigs can get up into the hundreds of dollars to have multiple jigs in multiple sizes, which is why the code is customizable up to .75 inch drill bits. Having one 3D printer could save a lot of money in this type of tool.

Bill of Materials[edit | edit source]

Drilling Jig ($0.40) https://www.youmagine.com/designs/drilling-jig

Tools needed for drilling are as follows:

Clamp ($6.40) amazon.com

Drill ($88.91) amazon.com

Tools needed[edit | edit source]

- MOST Delta RepRap or similar RepRap 3-D printer

Skills and knowledge needed[edit | edit source]

- Angle of the hole (30 degrees from X-axis)

Technical Specifications and Assembly Instructions[edit | edit source]

- Open the .SCAD file with the Jig

- Render the file into an .STL file

- Open the file in Cura

- Select settings that allow for 20 percent infill and 4 outer walls

- Build supports and choose zig-zag

- Use all other settings the same as for other prints

- Save the file as a .gcode

- Upload into Franklin and print!

Time to Print[edit | edit source]

1 hour for 120 mm/s speed with .2mm thickness

Instructions on using the Jig[edit | edit source]

- Place the jig where it is appropriate on the wood

- Clamp the jig to the wood

- Drill the hole into the wood

Cost savings[edit | edit source]

- $0.40 per jig

- $21.99

https://www.kregtool.com/store/c13/kreg-jigsreg/p114/kreg-jigreg-mini/

- $21.59 savings

98% savings!!!